When it comes to measuring steam flow, accuracy is everything. That's why many industrial applications turn to vortex flow meters. These meters are designed to provide precise, reliable measurements, even under the most challenging conditions. Whether you're monitoring flow rates in a steam boiler, heat exchanger, or other process, a vortex flow meter can get the job done.

Monitoring Steam Flow with Vortex Flow Meters

Vortex flow meters are a type of flow meter that use the Von Karman effect to measure the flow rate of fluids. This effect occurs when a fluid flows past a bluff body, such as a cylinder or a sphere. As the fluid moves around the bluff body, it creates vortices, or swirling patterns, in the wake of the body. By measuring the frequency of these vortices and applying mathematical formulas, vortex flow meters can calculate the flow rate of the fluid.

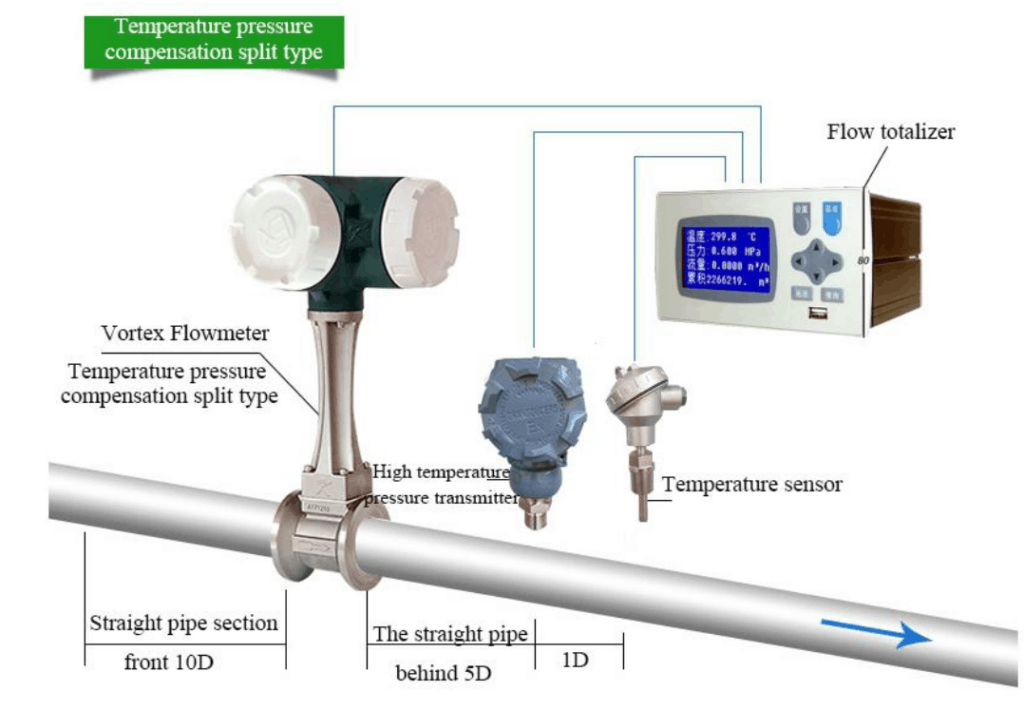

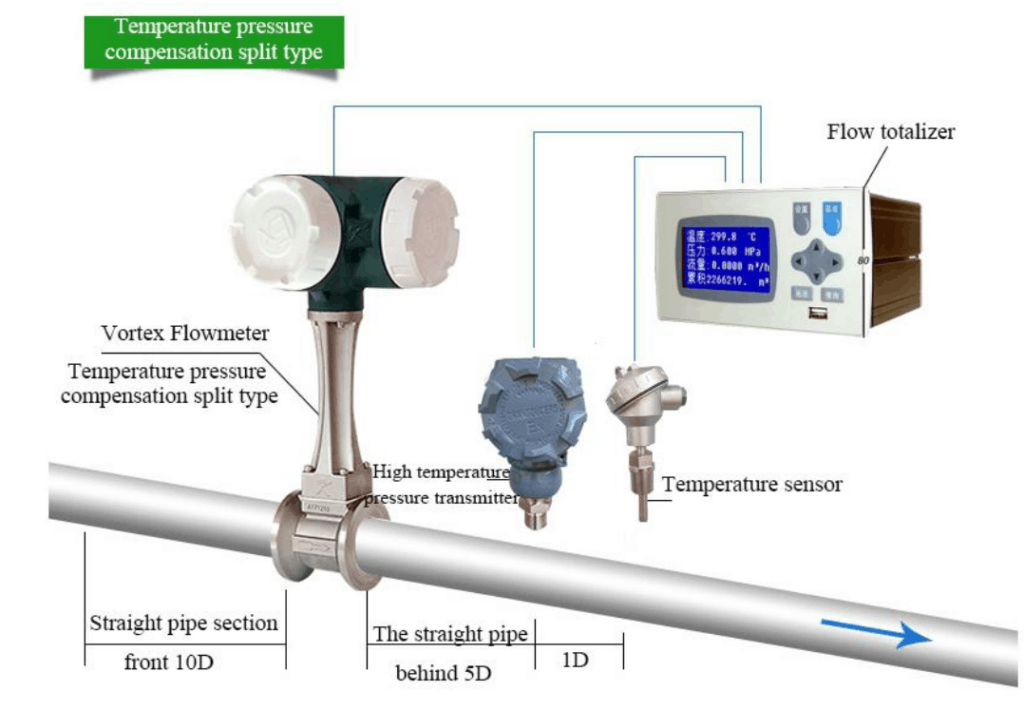

For steam applications, vortex flow meters are ideal because they can compensate for changes in temperature and pressure. Unlike some other types of flow meters, which require constant calibration to maintain accuracy under changing conditions, a vortex flow meter can adjust for these changes automatically. This makes it a popular choice for monitoring steam flow in industrial settings, where the conditions can vary widely.

The Benefits of Vortex Flow Meters for Steam Flow Monitoring

Here are some of the key advantages of using vortex flow meters for steam flow measurement:

Precision

Since vortex flow meters are designed to measure the frequency of vortices as they are shed from a bluff body, they can provide very accurate flow measurements. This makes them useful for both process control and billing purposes.

Reliability

Vortex flow meters are highly reliable because they have no moving parts that can wear out or break. They are also less susceptible to clogging or corrosion than some other types of flow meters. In addition, they can be used to measure the flow of a wide range of fluids, making them a versatile instrument for many different applications.

Cost-Effective

Compared to some other types of flow meters, vortex flow meters are relatively inexpensive. They also require very little maintenance and calibration, which can help reduce overall operating costs.

Applications of Vortex Flow Meters for Steam Flow Monitoring

Here are just a few examples of how vortex flow meters are used to monitor steam flow in various industrial applications:

Boiler Feedwater Monitoring

Steam boilers require a steady flow of feedwater to maintain safe and efficient operation. Vortex flow meters can be installed to measure the flow rate of feedwater into the boiler, ensuring that it receives the proper amount of water in real-time, even when steam demand fluctuates.

Heat Exchanger Monitoring

Heat exchangers are used to transfer heat from one fluid to another in a wide range of industrial processes. Vortex flow meters can be used to measure the flow rate of the steam entering and exiting the heat exchanger, allowing operators to calculate the efficiency of the heat transfer and optimize system performance.

Turbine Inlet Monitoring

Steam turbines are used to drive many types of industrial equipment, from pumps and compressors to generator sets. Vortex flow meters can be installed in the steam supply line to the turbine to ensure that it receives a steady, proper flow of steam, preventing damage or inefficiency.

Choosing the Right Vortex Flow Meter for Your Application

If you're considering a vortex flow meter for your steam flow monitoring needs, there are several factors to consider when choosing the right model:

Flow Range

Make sure the vortex flow meter you choose is capable of measuring the flow rates you need. Some models are designed for low flow rates, while others are better suited for high-flow applications.

Accuracy

Look for a vortex flow meter with the highest possible accuracy rating. This will help ensure that your flow measurements are as precise as possible.

Temperature and Pressure Capabilities

Be sure to choose a vortex flow meter that can compensate for changes in temperature and pressure, as this will help maintain accuracy under changing conditions.

Materials of Construction

Choose a vortex flow meter that is designed for the materials and fluids you will be measuring. Some models are better suited for corrosive or abrasive fluids, for example, while others are designed to handle high-temperature applications.

Conclusion

Vortex flow meters are a reliable, accurate, and cost-effective solution for monitoring steam flow in a wide range of industrial applications. By choosing the right model and installing it correctly, you can ensure that your process operates safely and efficiently, while minimizing downtime and costs.

Vortex Steam Flow Meter Applications

One of the key benefits of vortex flow meters is their ability to handle a wide range of fluid applications, including steam. Here are just a few examples of how vortex flow meters are used for steam flow monitoring:

- Steam boiler feedwater monitoring

- Heat exchanger monitoring

- Turbine inlet monitoring

- Condensate return monitoring

- Steam flow metering for energy billing purposes

As you can see, vortex flow meters have many different applications in the industrial world. Whether you're looking to improve steam boiler efficiency, optimize heat transfer, or just keep track of your energy consumption, a vortex flow meter can help.

Flow Measurement for Steam

When it comes to measuring steam flow, accuracy is essential. In industrial applications, even small errors in flow measurement can lead to significant inefficiencies or safety hazards. That's why it's important to use a reliable, accurate flow meter like a vortex flow meter when measuring steam flow.

Whether you're monitoring steam flow at a power plant, a chemical plant, or any other industrial facility, a vortex flow meter can be an invaluable tool. With its ability to compensate for changes in temperature and pressure, a vortex flow meter can provide accurate, real-time flow measurement, ensuring that your processes operate safely and efficiently.

If you are searching about VFM60MV MultiVariable Vortex Steam Flow Meter Mass Flow Indicates you've came to the right web. We have 7 Images about VFM60MV MultiVariable Vortex Steam Flow Meter Mass Flow Indicates like Vortex Flow Meter :: DN25 | Steam Flow Meters, Steam Flow Measurement-temperature&pressure compensation? and also Steam flow measurement | SICK. Read more:

VFM60MV MultiVariable Vortex Steam Flow Meter Mass Flow Indicates

www.comateflowmeter.com

www.comateflowmeter.com flowmeter multivariable

Vortex Flow Meter :: DN25 | Steam Flow Meters

www.bellflowsystems.co.uk

www.bellflowsystems.co.uk flow meter vortex meters steam dn50 dn150 dn25 dn200 dn100 dn65 dn80 model application bellflowsystems sensor

Steam Flow Measurement | SICK

www.sick.com

www.sick.com sick

Basic Of Flow Measurement Technique · CFD Flow Engineering

cfdflowengineering.com

cfdflowengineering.com Flow Measurement For Steam

flowerxflowers.blogspot.com

flowerxflowers.blogspot.com ultrasonic choice imagup

Steam Flow Measurement-temperature&pressure Compensation?

www.drurylandetheatre.com

www.drurylandetheatre.com pressure compensation

Vortex Steam Flow Meter|Temperature & Pressure Compensation

www.drurylandetheatre.com

www.drurylandetheatre.com vortex applicaitons compensation saturated drurylandetheatre

Vortex steam flow meter|temperature & pressure compensation. Vfm60mv multivariable vortex steam flow meter mass flow indicates. Vortex applicaitons compensation saturated drurylandetheatre

Post a Comment for "Steam Flow Measurement Units"