Flow meters are a crucial component in many industries, ranging from oil and gas to food production. Proper installation and maintenance of these meters is necessary to ensure accurate and reliable measurements. Here we will provide a guide to installing vortex flow meters and balance valves, with specific attention to recommended minimum pipe diameters for optimal performance.

Installation Guide for Vortex Flow Meters

Vortex flow meters are a popular choice for measuring flow in a variety of fluids, including steam, water, and gas. Installation of a vortex flow meter requires careful attention to detail in order to ensure accurate and reliable measurements. Here are the steps to install a vortex flow meter:

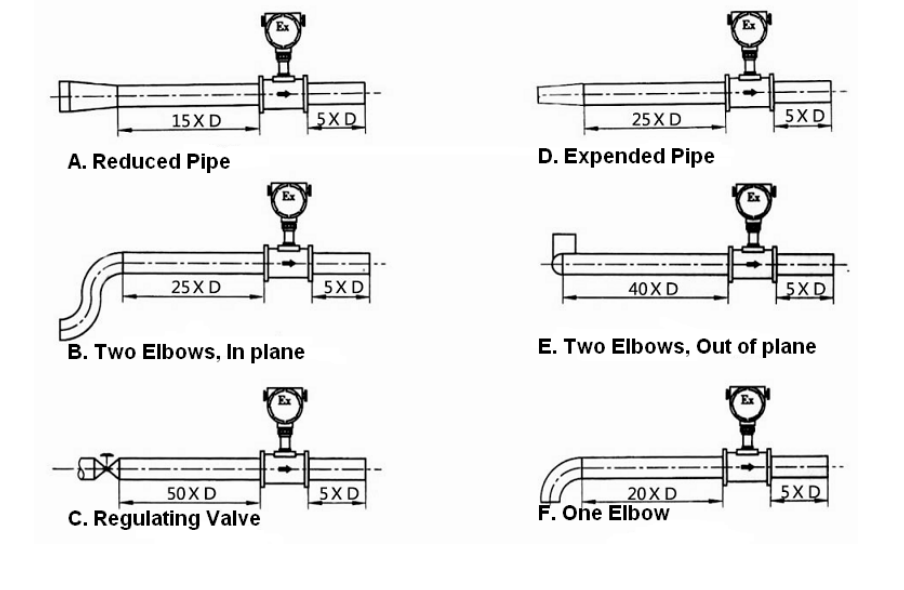

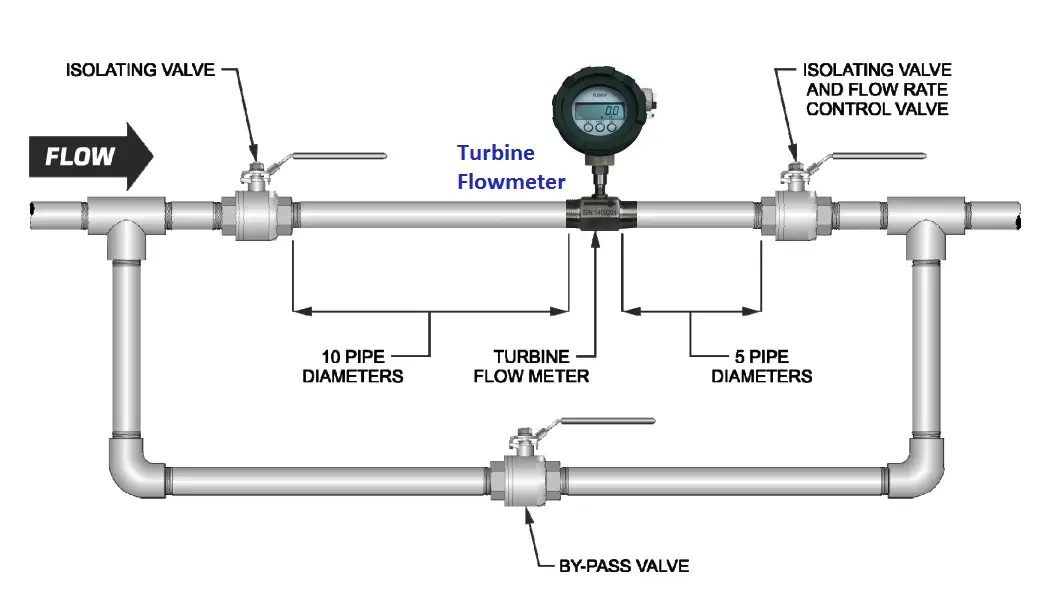

- Identify the installation location: The flow meter should be installed in a location that allows for a straight run of pipe both upstream and downstream of the flow meter. This will help to minimize turbulence and ensure accurate measurements. The flow meter should also be installed in a location that is easily accessible for maintenance and calibration.

- Prepare the pipe: The pipe should be cleaned and inspected before installation. Any debris or obstructions in the pipe can cause inaccurate readings or damage to the flow meter. In addition, the pipe diameter should be large enough to ensure that the maximum flow rate is not exceeded. Refer to the manufacturer's specifications for recommended pipe diameters.

- Mount the flow meter: The flow meter should be mounted in a vertical position to prevent the accumulation of debris or condensate in the flow meter. The orientation of the flow meter with respect to the direction of flow should also be considered, as this can affect the accuracy of the readings.

- Connect the piping: The flow meter should be connected to the upstream and downstream piping using flanges or other appropriate connectors. Ensure that the piping is properly aligned and tightened to prevent leaks or damage to the flow meter.

- Calibrate the flow meter: Once the flow meter is installed and connected, it should be calibrated to ensure accurate measurements. Calibration can be done using a variety of methods, including a master meter or a flow simulator.

Minimum Pipe Diameters for Flow Meters and Balance Valves

When installing flow meters and balance valves, it is important to consider the minimum pipe diameter required for optimal performance. The minimum pipe diameter will depend on a variety of factors, including the type of flow meter or balance valve, the fluid being measured, and the flow rate. Here are the minimum pipe diameters recommended for common types of flow meters and balance valves:

- Ultrasonic flow meters: For optimal performance, ultrasonic flow meters should be installed in pipes with a minimum diameter of 2 inches (50 mm).

- Turbine flow meters: Turbine flow meters typically require a minimum pipe diameter of 3 inches (75 mm) for accurate readings.

- Vortex flow meters: Vortex flow meters should be installed in pipes with a minimum diameter of 1.5 inches (38 mm) for optimal performance.

- Balance valves: The minimum pipe diameter for balance valves will depend on the type of valve and the flow rate required. Refer to the manufacturer's specifications for recommended pipe diameters.

It is important to note that these are general recommendations, and the minimum pipe diameter required for optimal performance may vary depending on the specific application. In addition, it is always a good idea to consult with a flow meter or valve specialist to ensure that the installation is properly designed and optimized for the specific application.

In conclusion, proper installation and maintenance of flow meters and balance valves is necessary to ensure accurate and reliable measurements. By following the recommended minimum pipe diameters and installation guidelines, industries can optimize their flow measurement systems and ensure efficient and reliable operation.

If you are searching about Upstream and Downstream Flow Straight Pipe Requirements-Flowmeter you've visit to the right web. We have 7 Pictures about Upstream and Downstream Flow Straight Pipe Requirements-Flowmeter like Turbine Flow Meter Installation Procedure | Instrumentation Tools, Instronline Instrumentation & Automation Products: Piping Requirements and also Vortex Flow Meter Installation Guide. Read more:

Upstream And Downstream Flow Straight Pipe Requirements-Flowmeter

www.drurylandetheatre.com

www.drurylandetheatre.com Vortex Meter Straight Run Requirements - Thorne-kishaba99

thorne-kishaba99.blogspot.com

thorne-kishaba99.blogspot.com Flowmeter Piping Requirements | Flow Measurement | Pipe (Fluid Conveyance)

www.scribd.com

www.scribd.com Turbine Flow Meter Installation Procedure | Instrumentation Tools

instrumentationtools.com

instrumentationtools.com meter flow installation turbine procedure piping upstream straight requirements strainer system components after flowmeter bypass line location filter plumbing setup

Flow Meter And Balance Valve Installation – Minimum Pipe Diameters For

www.deppmann.com

www.deppmann.com diameters determine

Vortex Flow Meter Installation Guide

vortex meter installation flow piping straight flowmeter requirements guide lengths upstream downstream meters line installations devices installed fewer claim differing

Instronline Instrumentation & Automation Products: Piping Requirements

pressurecalibrator.blogspot.com

pressurecalibrator.blogspot.com piping downstream flowmeter manometer rumus electromagnetic instrumentation boiler refinery automation paddle proposals ultrasonic

Upstream and downstream flow straight pipe requirements-flowmeter. Vortex meter straight run requirements. Meter flow installation turbine procedure piping upstream straight requirements strainer system components after flowmeter bypass line location filter plumbing setup

Post a Comment for "Flow Meter Piping Requirements"